Fasteners are an integral part of the purpose for holding machines, vehicles, and structures together. From bridges and heavy equipment to bicycles and home appliances, proper fastening ensures safety, durability and performance. Amongst the many types of fasteners in use today, it is the unique design and the fact that they are important for applications where vibration and movement are constant factors that make castle nuts stand out.

Castle nuts may not appear to be very special on first glance, but their design serves a purpose and an important one at that.

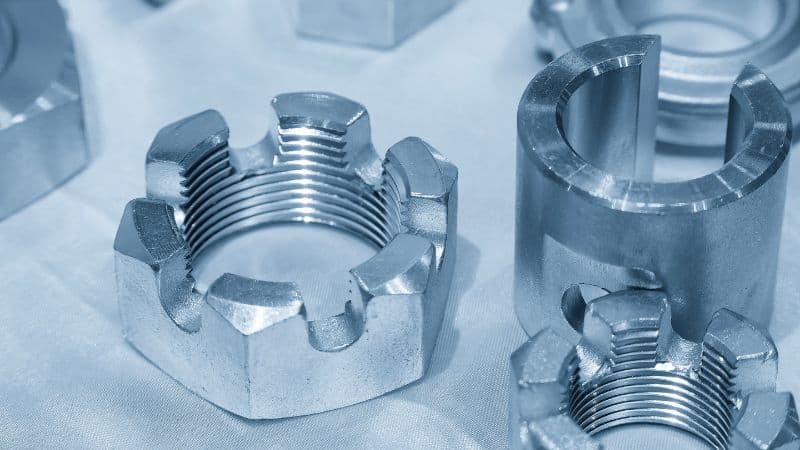

Understanding What a Castle Nut Is

A castle nut is a type of nut which has a series of slots cut into one end, giving it an appearance similar to the top of a castle wall. These slots are not for decoration. They are designed to work with a locking pin, most commonly a cotter pin, that passes though both the nut and a matching hole in the bolt.

Once installed correctly the cotter pin inhibits rotation of the nut. This provides a secure fastening system that is resistant against loosening under the influence of vibration, repeated movement or fluctuating loads. Because of this mechanical locking feature, castle nuts are often grouped as positive locking fasteners.

How Castle Nuts Work in a Fastening Assembly

The working principle of castle nut is very simple but very effective. The nut is threaded onto a bolt having a pre-drilled hole near the threaded end. After tightening the nut to a specified amount of torque, the installer aligns one of the nut’s slots with the hole in the bolt.

A cotter pin or split pin is then inserted through the holes that are aligned. The ends of the pin are bent outwards to hold it into position. Once the pin is installed, the nut is not able to rotate unless the pin is removed. This ensures that the nut remains locked in position in operation.

This method is not reliant on the friction. Instead, it relies on physical restraint to prevent movement, which makes it an especially reliable system in demand environments.

Why the Castle Shape Matters

The distinctive slotted shape of a castle nut is integral to its function. The slots provide multiple alignment options, allowing the nut to be secured at slightly different positions without overtightening or loosening beyond acceptable limits.

This flexibility is important when precise torque values matter. Rather than backing the nut off excessively to insert a locking pin, the installer can choose the nearest slot that aligns with the bolt hole while maintaining correct tightness. The result is a balance between proper torque and secure locking.

Common Applications of Castle Nuts

Castle nuts are chosen for applications where safety and reliability are essential. They are commonly used in systems that experience constant vibration, rotational forces, or dynamic loads.

In automotive applications, castle nuts are often found in steering systems, suspension assemblies, wheel hubs, and axle components. These areas are exposed to continuous movement and road vibration, making reliable locking critical.

In aerospace and aviation, castle nuts are used in landing gear components, control systems, and other critical connections. Aircraft operate under extreme stress conditions, and fasteners must remain secure throughout repeated cycles of takeoff, flight, and landing.

Industrial machinery also relies on castle nuts in areas where motion, load changes, and vibration could loosen standard fasteners. Heavy equipment, agricultural machines, and mechanical linkages frequently use castle nuts for this reason.

Even in smaller-scale uses such as bicycles, custom mechanical builds, and educational projects, castle nuts provide dependable fastening when movement and safety are considerations.

Materials Used in Castle Nuts

Castle nuts are manufactured in a range of materials to suit different operating conditions. Carbon steel is commonly used where strength and load-bearing capacity are priorities. Stainless steel is selected for environments where corrosion resistance is important, such as outdoor or marine applications.

Brass and other non-ferrous materials may be used in specialised applications where electrical conductivity or non-magnetic properties are required. The choice of material typically depends on factors such as load, environment, temperature, and exposure to moisture or chemicals.

Standards and Compatibility

To ensure consistency and interchangeability, castle nuts are produced according to established industry standards. These standards define dimensions, thread types, tolerances, and material requirements. Compliance with standards allows castle nuts to work reliably with matching bolts and locking pins across different applications.

Castle nuts are available in both metric and imperial sizes, making them suitable for a wide range of regional and international fastening systems.

How Castle Nuts Differ from Other Locking Nuts

Several types of locking nuts exist, but castle nuts offer advantages that make them suitable for specific uses. Unlike nylon-insert nuts, which rely on friction to resist loosening, castle nuts use a mechanical locking method that does not degrade with heat or repeated adjustments.

Compared to deformed-thread locking nuts, castle nuts allow for easier inspection and disassembly. The presence of a cotter pin makes it visually clear whether the nut is properly secured, which is especially valuable during maintenance checks.

This combination of reliability, visibility, and reusability makes castle nuts a preferred choice in safety-critical assemblies.

Installation and Maintenance Considerations

Correct installation is essential for castle nuts to perform as intended. The bolt must be compatible and include a properly positioned hole. The nut should be tightened to the specified torque before inserting the locking pin.

Cotter pins are generally considered single-use components because bending and straightening them weakens the metal. During maintenance, replacing the pin ensures continued reliability of the fastening system.

Regular inspection is recommended in applications where safety is critical. Checking for worn pins, corrosion, or movement in the assembly helps prevent failures before they occur.

Why Castle Nuts Still Matter Today

Despite advances in fastening technology, castle nuts remain relevant because of their simplicity and proven reliability. They offer a secure solution in environments where vibration and movement can compromise standard fasteners.

Their design makes them easy to inspect, service, and understand, even for those without advanced technical training. This combination of dependability and clarity ensures castle nuts continue to play an important role in mechanical fastening systems.

Conclusion

Castle nuts may appear simple, but they serve a vital role in fastening applications that demand reliability and safety. Their slotted design, combined with a mechanical locking pin, provides resistance to loosening that few other fasteners can match.

From vehicles and aircraft to industrial machinery and everyday mechanical systems, castle nuts help ensure components stay securely connected. Understanding how they work and why they matter highlights the importance of even the smallest components in keeping complex systems functioning safely and effectively.